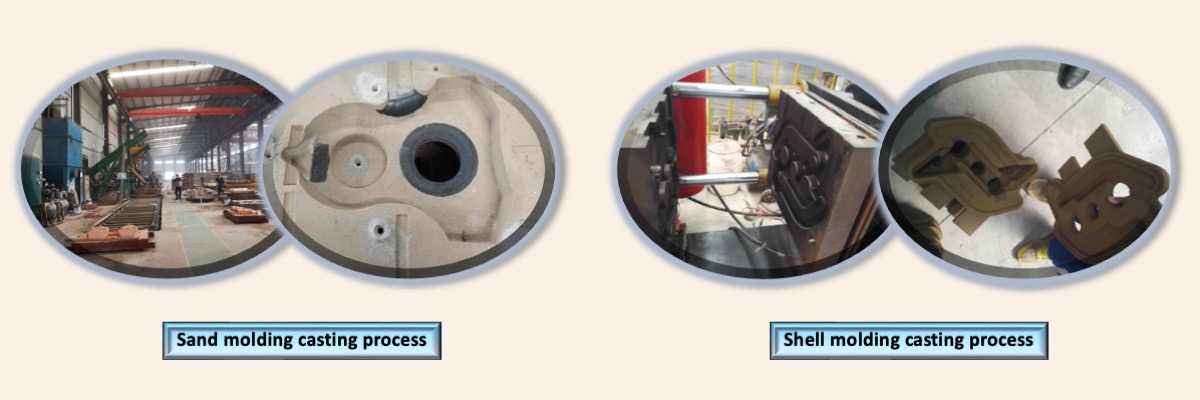

Manufacturing Processes:

Sand, Shell, Foam casting processes plus excellent in-house machining capacibilty

Material:

✔ Low alloy steel

✔ Manganese steel

✔ Carbon steel

✔ Stainless steel

✔ Ductile iron

Melting & Pouring:

✔ (1) 0.75 tons and (2) 2 tons induction furnaces with argon bubbling refining

✔ (1) 2 tons AOD refining furnace

✔ Bottom pour ladles with gas pre-heating to 900 C

Annual Capacity in Tons:

5,000 tons. Current capacity loaded 3,000 tons.

Heat Treatment:

Electric, car-bottom furnaces with 1,300 C max temperature:

✔ Annealing

✔ Normalizing

✔ Air, oil, water quenching

✔ Tempering

✔ Induction Tempering

✔ Water tank size : 5 m length x 3 m width x 5 m depth

✔ Oil tank size : 1.9 m length x 1.5 m width x 1.3 m depth

Machining:

✔ Has 7 CNC machining centers with New Monarch, Hass, Fair Friend brand. Meet +/- 0.01 mm tolerance

✔ Horizontal Boring / Milling machine. Tolerance +/- 0.01 mm

✔ CNC Lathe up to Dia 800 mm. Tolerance +/- 0.01 mm. Other drilling, taping machine

Part Weight: Up to 2,500 KGs

As Cast Tolerance to Meet: ISO 8062 CT 10 – 12

NDT:

✔ MPI & PT per ASTM E709 & E1444 - 2 Level – II qualified employees

✔ UT per ASTM A609, Din 12680-1, -2 - 2 Level –II qualified employees

✔ RT per ASTM E94, E1030 - Up to 400 mm thick, outsourced

✔ VISUAL SURFACE TO MSS SP-55 & ASTM A802

Chemical Analysis:

SHIMADZU GVM-514 - vacuum emission spectrometer, 26 channels installed.

Can analysis C, Si, Mn, S, P, Cr, Mo, Ni, Cu, Re, Mg, N, Zr, B, Al, V, Ti and so on

Mechanical Properties: Tensile, yield, elongation, reduction

Toughness Testing: Charpy ”V”, “U” notch under room and -60 ℃ temperature.

Hardness Testing: Rockwell, Brinell, Leeb

Layout: CMM and 3D laser scanning