1 - 2 tons, 1 - 0.75 ton and 1 - 0.5 ton induction furnaces.

Melting carbon, low alloy and stainless steel

1 - 3 tons AOD refining furnace. Perfect for stainless steel castings

Bottom ladle gas pre-heating system. Heat ladle to 900℃

Molding - Ceramic sand with sodium silicate binder, CO2 gas hardening.

Shell molding machines - to make shell or critical sand core for tight tolerance part.

Vertical shell molding machine with size 700 x 600 x 550 mm

Horizontal shell molding machine with size 1,000 x 900 x 800 mm

Core making - Wood, Plywood, Aluminum core boxes.

Patterns - Wood, plywood, aluminum with steel tube frame underneath

Sand flasks with all size

Pouring area - Gas exhausting design to eliminate pollution

Shake - out

Shot blasting machine to remove residual sand and scales

Arc air - to remove ingate, riser residual from castings.

Fettling - 20 working stations for casting fettling

HT furnaces - Car bottom electric furnaces. Heat castings to certain temperature

6 points temperature detectors to ensure temperature uniform. Furnace temperature uniform to be tested every year.

500 tons Pressing machine - To adjust size of castings, achieve requested flatness

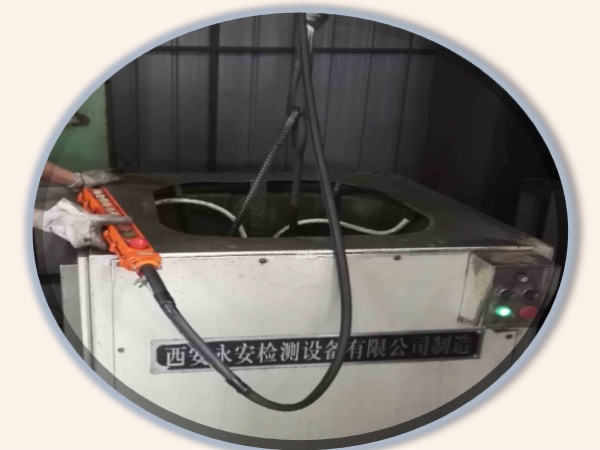

Maganitic particle tester - Well type and rotating type

Wet fluorescent magnetic particle applied

Machining shop

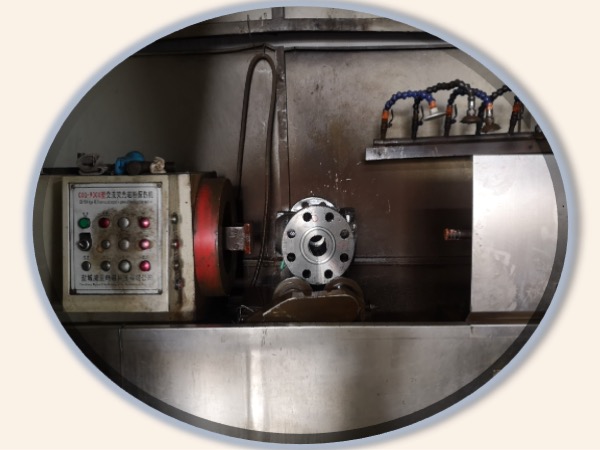

CNC machine centers - 7 sets CNC machining centers and boring & milling machines equipped. 5 sets CNC lathe, and more than 20 other machining equipment. Can do drilling, tapping, turning, milling, boring.

Manganese Concaves & Mantles Machining by CNC Vertical Lathes

Manganese Jaw Plates Machining